Automated Sortation Electrical Control and Software Connection

Product Description

In the aspect of SCADA, through real-time monitoring of equipment status, we can know the running status or alarm types of all kinds of equipment in time, which ensures the rapid repair of the system. Through the collection and chart analysis of all kinds of data, the dynamic efficiency, average efficiency, peak efficiency, misclassification rate, reflux rate and other production indexes of each thread can be grasped intuitively in real time. Our company has many senior electrical and software engineers, who has rich experience in the control and communication of matrix sorting system, cross belt sorting system, automatic loading sorting system and automatic parts supply system.

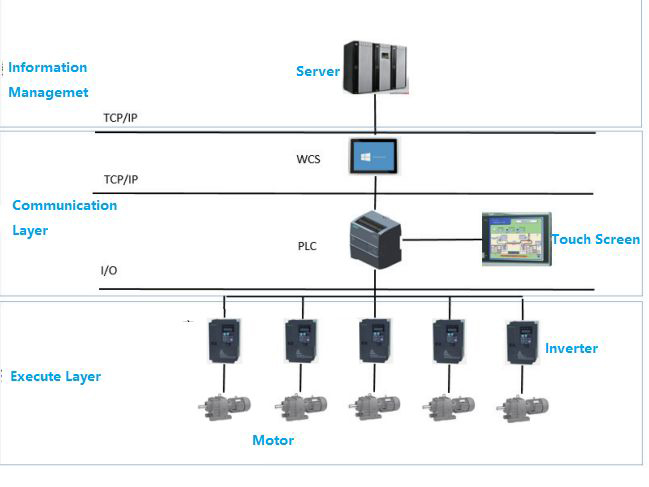

Information system

System description

- The main control system connects to Express Company’s upper information system through the network to provide data support, it connects to the equipment control system through the control network to collect data and monitor the production process. The main functions include communication, monitoring, diagnosis, management, etc.

- The system obtains the information of waybill and route from the upper information system, and provides the information like sorting results for it, it carries out unified scheduling for the sorting process of waybill downward, and monitors, controls and manages the sorter system and conveying system equipment as part of the production management, equipment management, safety management, etc., this way it carries out the scheduling and execution of package sorting. The system contains servers, management terminal, query terminal, operation terminal, network facilities, etc.

System architecture

- ADM: Automatic sorting management system

- ADLM: Automatic sorting assistant management system

- MIS: Management information system

External system: Customer's ERP or MES Work process

- BCR C: Barcode Reader Client

- SAS: Sorting Auxiliary System

- WCS: Warehouse Control System

WCS system WCS

Barcode identification. Reading the barcode: Static reading at the induction.

Sorting function.

- It can automatically read the barcode on the package, and confirm the target chute according to the barcode and sorting scheme, so that the package can be correctly sorted into the proper chute.

- For abnormal express packages, according to different abnormal conditions (no information, no route, etc.), the packages are sorted to different reject chutes.

- Record the information of the goods that fall into the bag and bind these information to the barcode of the big bag.

- It can download waybill data in real time, and can store no less than 50,000,000 entries of waybill data.

- It can upload the information related to the waybill sorting process to your upper computer.

- Algorithmic logic for allocating chute: circulation.

- MIS system MIS Sorting scheme management. Basic setting of logic chutes.

- Basic setting of reject chutes.

- Sorting scheme setting: It sets the corresponding relationship between the chutes and the logic chutes.

- Shift management. The system sorting requires shift start and end management. The shift can be managed one by one.

- For sorting task management, each sorting task can have a different sorting plan

Sorting result query.

Users may obtain the sorting information of the current shift, or the sorting information of the historical shift.

Users may obtain the communication log, etc.

Query the sorting information of each package in the current sorting task and the historical sorting task, such as code scanning time, infeed time,outfeed time, chute number, induction number, and whether the sorting was successful, etc.

Statistical report.

- Statistics of sorting efficiency of induction: The sorting efficiency of each induction per hour is counted and shown in charts.

- Statistics of sorting quantity: Daily sorting quantity statistics and sorting quantity statistics of each shift.

- Chute throughput statistics: Throughput statistics of each chute.

Data management

- The system regularly backs up the waybill information table, sorting result information table and system log table in the database.

- Generally, the waybill information table stores data of 2 to 3 months, and is automatically backed up after expiration.

- Generally, the sorting result information table stores data of 2 to 3 months, and is automatically backed up after expiration.

- The system log table is generally saved for half a year, and is automatically cleared after expiration.