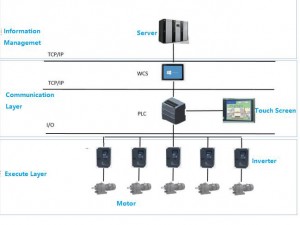

Automated Cross Belt Sorting Solution

Structure Principle

The cross belt sorter adopt linear motor driving the end-to-end carts or trolley queue to transmit at high speed on the loop or linear railway.

The main sorters are composed of many carts queue and these carts were small & bidirectional conveyor belt. Each cart was driven by independent conveying belt. The conveyor belt is perpendicular to the running direction of the carts.

Parcels with barcode can infeed into carts automatically or semi-automatically through parcel infeed table. After the parcel destination located by the Automatic recognition and location system, the carts’ belt started to convey and unloading to achieve the parcel sorting work.

The main components of the cross sorter include: frame, track, linear motor, trolley/carts, grid chute, supply machine (Parcel Induction conveyor), Isolated conductor rail(ICR), RCoax radiating cable.,etc

There is loop and linear cross belt sorter system

(1) Loop operation: the power supply supplies power to the linear induction motor to generate magnetic force, and the magnetic force pushes the secondary aluminum plate forward to realize the Cross sorter loop working.

(2) Electric roller movement: two or more 48V DC power supplies supply power to the electricity taking track, and the brushes take electricity from the electricity taking track and supply it to the electric roller of the sorter carts, to realize the positive and negative rotation of the sorter cart.

Application:

Cross Belt Sorter could handle below products size:

| Length | 100mm to 600mm |

| Width | 100mm to 400mm |

| Height | 5mmto 400mm |

| Weight | 10g to 5Kg |

Requirements for Sorted Parcels

Cross belt sorter can effectively adapt to the actual situation of products, can automatically identify the bar code on the courier bill, and completely obtain the parcel information contained in the code and sort it after reading.

Parcel requirements:

Ensure that the bottom of the parcel on board is flat and could not roll over;

Ensure that the barcode of the parcel bill on the machine is flat and clear;

Cylinder-shaped ,ball and special-shaped parcels can't go to the sorting carts because they can rotate on the conveyor belt.

Cross belt sorter productivity

There are 3 kinds speed 2.0m/s, 2.2m/s, 2.5m/s to change by single button.

|

Main Technical Item |

Parameter |

||

|

Main loop speed: |

2.0m/s |

2.2m/s |

2.5m/s |

|

Sorting capacity under Single parcel induction (Theory) |

12000PC |

13200PC |

15000PC |

|

Sorting capacity under Single parcel induction (Practical) |

9600PC |

10560PC |

12000PCS |

|

Cart distance |

600mm |

600mm |

600mm |

|

Sorting chute |

750mm |

750mm |

750mm |

|

Wrong sort rate |

Less than 0.01% |

||